Brug Bi-Plast i din

Produktudvikling

Fra idé til serieproduktion

– er Bi-Plast en del af dit projektteam

Bi-Plast processerer, udvikler og sprøjtestøber tekniske emner i termoplast.

Vi påtager os alle typer opgaver, hvor vi kan fungere som din tekniske sparringspartner gennem hele udviklingsprocessen fra idé til færdigt emne.

Bi-Plast sprøjtestøber plastemner i alle termoplaster

– med undtagelse af PVC.

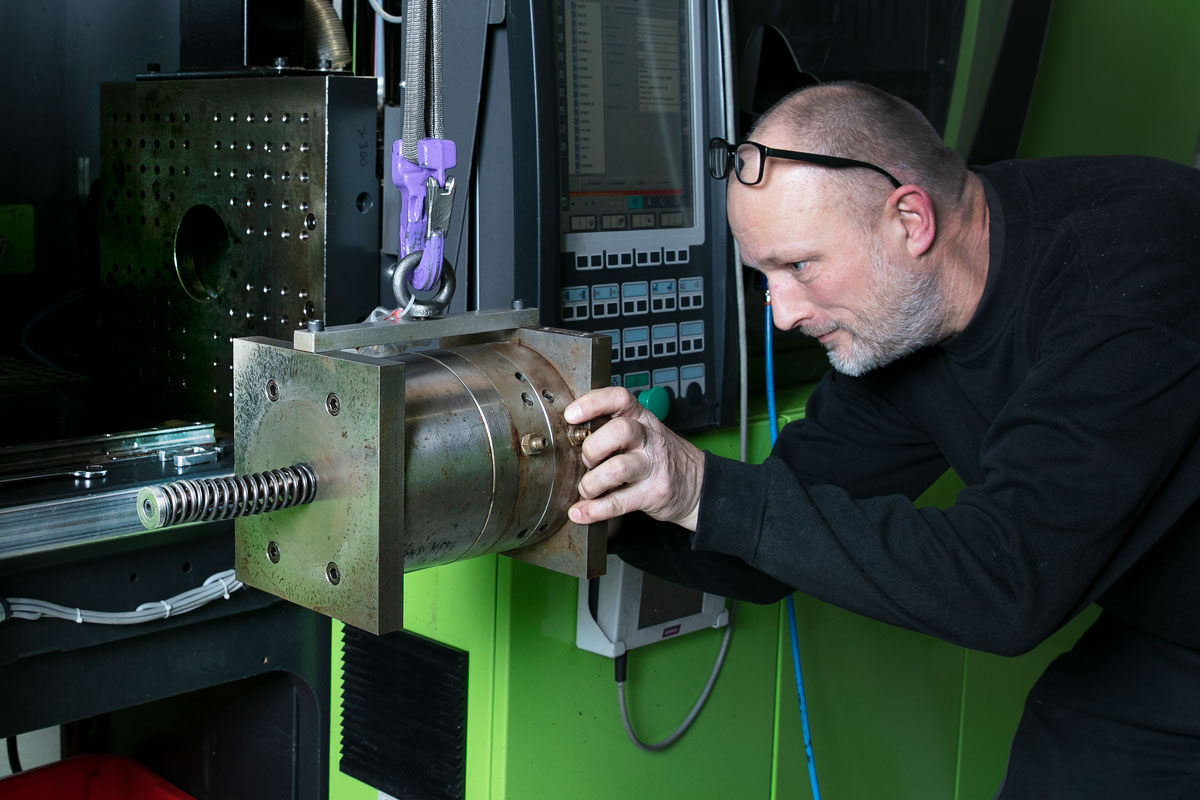

Sprøjtestøbning

Bi-Plasts erfaring med sprøjtestøbning i plast går tilbage til 1972.

Vi stiller al vores erfaring med 1 og 2 komponent støb til rådighed for dig og sprøjtestøber dine tekniske emner i en høj og ensartet kvalitet.

Monosandwich støbning

Bi-plast er specialist i Monosandwich støbning – et godt og økonomiske alternativ i 2K-støbning.

En effektiv 2K metode, som vores kunder er meget glade for!

Miljøpolitik

Bi-Plast har taget stilling og vil løbende forbedre den miljømæssige indsats.

Godt fra start - spar tid og penge

Vi sætter en ære i at tænke os om! – og i fællesskab med kunden komme godt fra start med en god dialog.

På den måde sparer vi tid og penge, fordi produktet ikke skal justeres om.

Resultatet er en hurtigere levering samt en kortere og dermed billigere udviklingsfase.

Certificeringer

For at sikre en ensartet og høj kvalitet er Bi-Plast ISO 9001 certificeret.

Desuden sætter vi dagligt fokus på miljøet bl.a. gennem vor ISO 14001 certificering.

Kontakt os

For at kunne sende en besked gennem vores kontaktform bedes alle cookies accepteres.

Bi-Plast ApS

Græsholmevej 57

5700 Svendborg

CVR-nr: 53209718

Tlf. 62 22 19 00

mail@bi-plast.dk